Industry News

NEWS

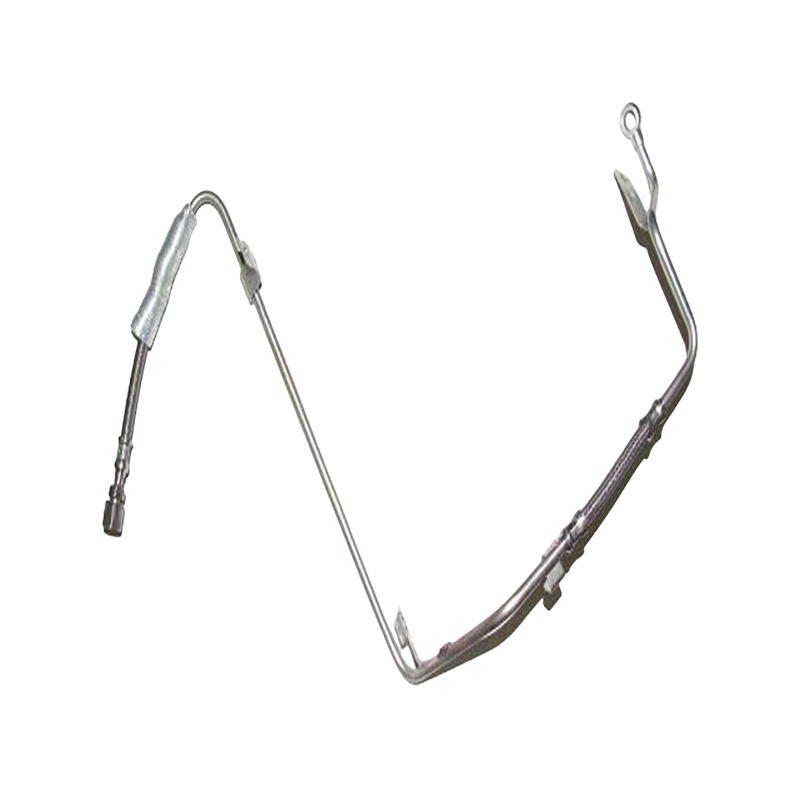

How Can a Simple Fluid Line Solve Major Transmission Overheating Issues?

Vehicle owners often overlook the intricate network of lines and hoses that keep their cars running smoothly. While the engine gets most of the attention, the transmission is equally critical, and it operates under intense heat and pressure. When temperatures rise too high, the transmission fluid breaks down, leading to slipping gears, delayed engagement, and eventual failure. This brings many drivers to ask a pressing question: How can I prevent my transmission from overheating without expensive modifications? The answer often lies in the quality of the components responsible for cooling that fluid, specifically the Cooler Line Assembly.

The Vital Role of Fluid Circulation

To understand why the correct lines matter, one must first understand how a transmission stays cool. Transmission fluid serves two purposes: it lubricates the moving parts inside the gearbox and transfers heat away from them. This hot fluid is pumped out of the transmission, travels to the radiator (or a dedicated cooler) where it releases heat, and then returns to the transmission to repeat the cycle.

If this flow is interrupted, even for a moment, temperatures can spike dangerously. Old, corroded, or leaking lines restrict this essential circulation. This is why replacing a worn line with a precision-engineered component is not just a repair; it is a preventative measure against significant mechanical failure.

Recognizing the Signs of Wear

Unlike a flat tire or a dead battery, a failing transmission line often gives subtle warnings at first. Ignoring these signs can lead to being stranded on the roadside. Drivers should be aware of the following indicators:

- Puddles under the vehicle: Transmission fluid is typically red or pink and has a distinct sweet smell. If you see these spots where you park, the lines are likely leaking.

- Burning odor: If fluid is leaking onto hot engine parts or if the transmission itself is running low on fluid due to a leak, you may smell something burning.

- Difficulty shifting gears: Low fluid levels caused by a leak can result in erratic shifting behavior, such as hesitation or jerking when the car changes gears.

Why Precision Engineering Matters

Not all replacement parts are created equal. In the past, generic "one-size-fits-all" lines were the norm. Mechanics often had to bend, cut, and flare metal tubes to make them fit a specific vehicle. This process was time-consuming and, if done incorrectly, could lead to kinks in the line or poor connections that eventually leak.

Modern replacements are designed with exact specifications in mind. A Cooler Line Assembly that is precision-engineered ensures that every bend matches the original routing of the vehicle. This eliminates stress points where metal fatigue could cause a crack later on. Furthermore, the connections are designed to seat exactly as the original equipment did, ensuring a tight seal that withstands the high pressure generated by the transmission pump.

Installation and Longevity

One of the main benefits of using a direct replacement part is the ease of installation. For DIY mechanics, this is a significant advantage. When the lines are pre-bent and the fittings are exact, the repair becomes a straightforward remove-and-replace job. This reduces the time the vehicle spends in the shop and minimizes the chance of installation errors.

Longevity is the other key factor. High-quality materials resist corrosion from road salt and debris. By ensuring a leak-free path for the fluid, the transmission maintains the correct pressure and temperature. This directly correlates to a longer lifespan for the transmission itself, saving the owner thousands of dollars in potential repair costs down the road.

Technical Specifications at a Glance

When shopping for replacement parts, having clear data helps in making an informed decision. The table below outlines the key features of this specific replacement part, designed to fit vehicle requirements precisely.

| Feature | Specification |

|---|---|

| Function | Transports transmission fluid to and from the cooler for heat dissipation. |

| Construction | Precision-engineered steel or aluminum alloy with high-quality fittings. |

| Fitment Type | Direct OEM replacement; designed for exact alignment with factory mounts. |

| Primary Benefit | Ensures leak-free operation and maintains consistent fluid pressure. |

| Compatibility | Designed to match specific OEM requirements for a secure connection. |

Protecting Your Investment

A vehicle is a complex machine, and its components rely on each other. The transmission is one of the costly parts to replace or rebuild. Therefore, protecting it with relatively affordable, high-quality maintenance parts makes financial sense. By ensuring that the fluid lines are in good condition, you are effectively protecting the heart of your vehicle's drivetrain.

Regular inspections of the Cooler Line Assembly during oil changes can catch potential leaks before they become severe. Look for signs of rust on the lines or dampness around the connection points. Replacing these lines at the first sign of wear is a proactive step that pays off.

The Importance of Direct Fitment

Many car owners wonder if they can simply patch a leaking line or use a generic hose. While patching might offer a temporary fix, it is rarely a reliable long-term solution. The pressure inside a transmission line can fluctuate wildly while driving. A patch or a clamp that is not rated for this specific pressure can blow off, causing a sudden and total loss of fluid. This leads to immediate transmission damage.

Furthermore, generic hoses may not have the same internal diameter, which can alter the flow rate of the fluid. Too slow, and the fluid overheats; too fast, and it might not dissipate heat effectively. Direct fitment ensures that the hydraulic dynamics of the system remain exactly as the manufacturer intended.

Final Thoughts on Maintenance

Maintaining a vehicle requires attention to detail. While engine oil changes are routine, the transmission cooling system is often neglected until a problem arises. By understanding the critical role of the lines and choosing a precision-engineered replacement, drivers can avoid common pitfalls associated with transmission overheating.

Investing in a high-quality Cooler Line Assembly provides peace of mind. It ensures that the transmission operates within the correct temperature range, delivers smooth performance, and lasts for many miles to come. For anyone experiencing symptoms of a leak or overheating, inspecting these lines should be the priority. It is a small component that plays a large role in the reliability of the vehicle.

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ©NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English Español

Español